Peel Back the Layers – Advanced Non-Destructive 3D imaging

Understanding porosity, ingredient distribution, and defects

Understanding porosity, ingredient distribution, and crack characteristics (location and thickness) is crucial for product development and optimization. Our imaging service provides insights into the internal structure of a wide range of materials, including pharmaceuticals, biological samples, food, composites, and electronics.

We use advanced Micro-CT scanning technology for non-destructive investigations, allowing us to capture detailed 3D representations of your products. This technique enables the examination of micro-scale features, offering both qualitative and quantitative analyses to facilitate product comparison and improvement.

For samples with specific characteristics, such as low-density biological materials, we enhance our imaging capabilities with Synchrotron tomography. This technique, combined with phase contrast tomography, provides better contrast and detail, enabling the investigation of features which would be otherwise invisible.

How can we help you?

- Visualization of your product’s internal 3D structure

- Characterization in different steps of your manufacturing process – with the same piece of material or product

- Localization and control of internal components in a product – are they correctly placed in relation to each other?

- Qualitative comparisons of porosity and other structural sample characteristics

- Micro-CT scanning is optimized for high resolution analysis of samples

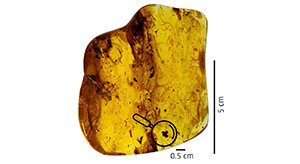

Case Study: Advanced technology identifies 40-million-year-old flower

Case Study: Advanced technology identifies 40-million-year-old flower

An unusually well-preserved flower encapsulated in amber was analyzed by specialists from the Danish Technological Institute using advanced synchrotron technology.

Read more

Case Study: Porosity in pharmaceutical products

Case Study: Porosity in pharmaceutical products

The porosity of two medicine tablets are investigated with Micro-CT scanning, high-pressure mercury intrusion and gas adsorption techniques. The porosity of a tablet is described from the pore size as well as the distribution of the pores, which together have a great influence on the quality of the tablet. Porosity measurements are used as an indicator of the tablet's durability, air and moisture penetration as well as the tablet's robustness.

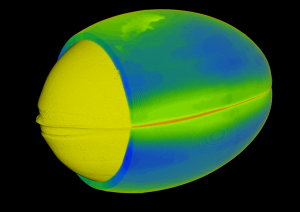

Read more Case Study: Capsule thickness in 3D

Case Study: Capsule thickness in 3D

A fish oil supplement pill is investigated using Micro-CT scanning. The 3D analysis enable measurements and visualizations, and the volume of the fish oil and the capsule can be determined.The investigation is furthermore used to identify flaws and weaknesses in the capsule.

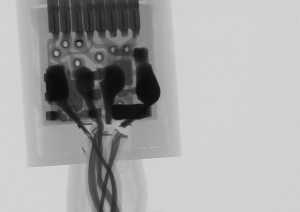

Read more Case study: Failure analysis of critical materials

Case study: Failure analysis of critical materials

We present 3D imaging data collected for electronics and tube failure. We use Micro-CT scanning to investigate failure in pharmaceutical and food production where maintaining the integrity and quality of materials is vital. We help you detect and analyze defects in tubing, gloves, and electronic components with thoroughness and accuracy.

Read moreCase study: Pellets & phase contrast

In this case study, pellets were visualized by both laboratory micro-CT and phase contrast tomography (HiP-CT, synchrotron source). With the addition of phase contrast, it's possible to distinguish between different types of organic material.

Read more

Case study: Soft tissue in small fish

In this case study, we used phase contrast tomography at the ESRF to image fish with unprecedented detail in the internal organs. The purpose of the investigation was to study the digestion of various experimental diets. With the three-dimensional tomography data, it's possible to study the digestion of experimental feed as it passes through the fish.

Read more

Case study - Porosity of foam

Case study - Porosity of foam

We have investigated the porosity of a foam material using Micro-CT, SEM, and Mercury Intrusion Porosimertry. The study demonstrates how we combine techniques, to get a more in-depth understanding of the materials characteristics on the micro- and nanometer level.

Read moreCombined Analysis Methods Give the Best Results

Our team has more than 25 years of experience solving characterization tasks for our customers and we often combine results from several separate types of characterization to give you the best possible answer to your needs. Sometimes, a sample is first characterised with Micro-CT and additional information can be added, by doing characterisation with electron microcopy (SEM).

In our labs we perform characterisation with light microscopy, scanning electron microscopy (SEM/EDX, FIB/SEM), infrafred spectrocopy (FT-IR), X-ray diffraction (XRD) and Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS).

Please contact our Susan Rudd Cooper for more information. She can be reached at srco@dti.dk or +45 7220 1754.