Failure Analysis of Critical Materials

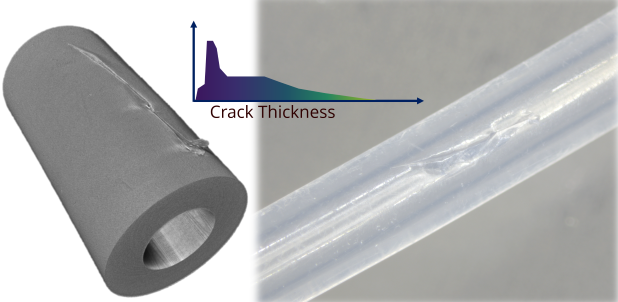

Micro-CT analysis of materials helps determine extent, location and cause of cracks and breakage

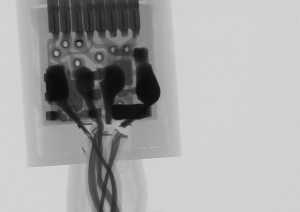

In pharmaceutical and food production, maintaining the integrity and quality of materials is vital. We offer services using 3D imaging to help you detect and analyze defects in tubing, gloves, and electronic components with thoroughness and accuracy.

In pharmaceutical and food production, maintaining the integrity and quality of materials is vital. We offer services using 3D imaging to help you detect and analyze defects in tubing, gloves, and electronic components with thoroughness and accuracy.

We use state-of-the-art Micro-CT technology to provide detailed 3D visualizations of your materials. This technique enables internal examination without the need for physically opening and damaging the material.

We can resolve microscale details and offer a comprehensive view of any defects, including their size and, in some cases, the direction of punctures.

This capability benefits you by determining where a fault is, allowing you to repair instead of discarding a part, and identifying if it is a single component or the entire machine that has failed.

Our Process

- Material Submission: Deliver the item you need investigated to us.

- 3D Scanning: We use Micro-CT to scan your material.

- Detailed Analysis: The scan produces a stack of thousands of images that are used to visualize the material in three dimensions.

- Comprehensive Reporting: We provide a detailed report highlighting the microscale defects and other critical findings.

Key Benefits

- Avoid Waste: Identify cracks and defects early, potentially saving entire batches of materials that need to be kept air-free.

- Verify Integrity: Ensure the air-tightness of your products by detecting and analyzing cracks or holes.

- Prevent Future Failures: Understand the cause and extent of breakages to prevent recurrence.

- Detailed Insights: Determine the size, direction, and depth of punctures or defects to take precise corrective actions.

- Targeted Repairs: Identify specific faults in electronic components, allowing for precise repairs rather than replacing entire parts or machines.

Visualization and investigation of crack thickness in tubing using color-coded distance mapping.

Additional Techniques

Beyond Micro-CT, we offer a suite of complementary techniques to ensure the most thorough analysis possible. Whether you need additional imaging methods or material testing, we have the tools and expertise to meet your needs.

Ready to enhance the quality and integrity of your materials? Please contact our specialist Olivia Aalling-Frederiksen for more information. She can be reached at ofr@dti.dk or +45 7220 3042.