Ultrathin crystals generate disinfecting UV light

With the help of the Danish Technological Institute's specialists within advanced surface coatings, UV Medico has validated a method for producing ultrathin crystals that can be used in UV light sources for safe disinfection.

Imagine being able to disinfect entire rooms without lifting a finger, all while sitting in the room.

This could be useful in production halls with strict hygiene requirements or in healthcare facilities such as hospital waiting rooms or operating theaters.

That is precisely what the technology company UV Medico is working to develop. Their technology uses advanced crystals to halve the wavelength of light, converting it into a specific UV frequency known as far-UVC. This type of light inactivates bacteria, viruses, and even inhibits mold growth. Moreover, far-UVC is safe for humans, meaning it does not harm the skin or eyes, unlike certain other types of UV light.

A MADE Kickstart project allowed UV Medico to quickly and effectively test an idea that could be pivotal for their product development.

A new way to create ultrathin crystals

A new way to create ultrathin crystals

The idea was to investigate a new method for creating ultrathin layers of crystals, which are crucial for UV Medico’s light sources. Additionally, UV Medico aimed to explore whether these crystal layers could be produced in Denmark, thereby avoiding international dependencies.

Using ion irradiation, where protons are shot into the material with high precision, the goal was to create a controlled fracture surface that could be used to produce the thin crystal layers.

- The Kickstart project was a way to test whether our idea was feasible. It gave us the opportunity to collaborate with the Danish Technological Institute and access their expertise and unique facilities without requiring a large initial investment. The aim was to find a method to work with the fragile crystals without damaging them, says Nicolas Volet, CTO and co-founder of UV Medico.

And the results were positive.

- We have now confirmed that it is possible to create thin layers of crystals using ion irradiation. This provides us with an entirely new way to produce components for our UV light sources, Emil Zanchetta Ulsig, development engineer and co-founder of UV Medico, explains.

Advanced technology paved the way

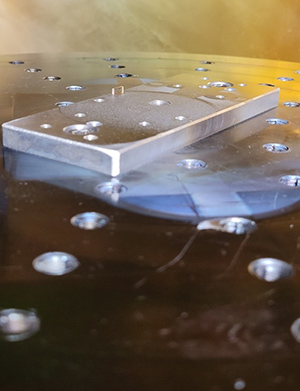

To test the idea, the Danish Technological Institute used an advanced ion accelerator- a unique facility that allows extreme precision when shooting protons into materials.

- Our task was to test whether we could use ion irradiation to create a controlled fracture surface in the crystals without damaging the material, says Albert Viñas Muñoz, senior consultant at the Danish Technological Institute.

This is a technique that requires very precise energy levels so that we can hit exactly the desired depth in the material. In this way, we can create a kind of ‘weakness’ in the crystal, making it possible to split it into nanometer-thin layers

- Albert Viñas Muñoz, Danish Technological Institute

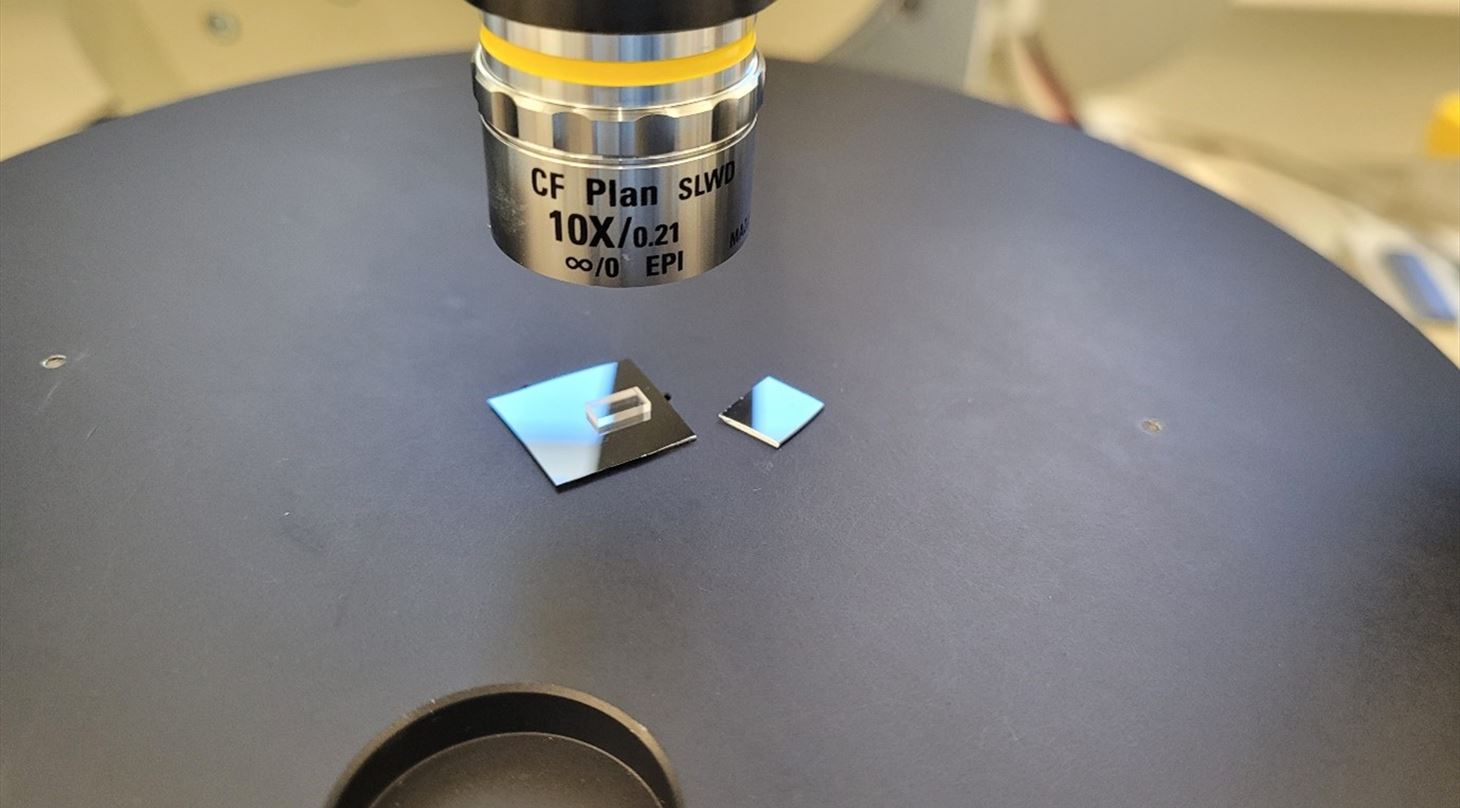

The tests were conducted with BBO crystals, which are both fragile and hygroscopic, meaning they are prone to damage or moisture absorption during processing. To ensure the material wasn’t damaged by the ion irradiation, the Danish Technological Institute analyzed the crystals both before and after the process.

- We conducted a series of controlled experiments where protons were shot into the crystals, and we then measured whether the material remained intact. It was about finding the right balance to create a controlled fracture surface without damaging the crystal, says Albert Viñas Muñoz.

Validation of the idea and next steps

The project showed that the method works. It allows us to produce the thin crystals we need. This is an important validation of our idea

- Nicolas Volet, UV Medico

UV Medico has already taken the next step, which is to apply for another MADE project, this time a MADE Demonstration project.

- The next project is about demonstrating the thin film and achieving a thickness below 1 µm, as well as taking what we’ve learned and delving deeper. We want to understand what happens in the material at the atomic level so we can optimize the process and make it more stable, Emil Zanchetta Ulsig explains.

The upcoming MADE project will likely also involve collaboration with the Danish Technological Institute.

- We hope to continue the partnership with the Danish Technological Institute. They have been an important partner in this project, and their expertise and facilities are something we want to build upon in the future, says Nicolas Volet in conclusion.

In addition to its applications in disinfection, far-UVC also has potential in other technological areas. For example, the technology can be used in communication, where light transmits data without requiring a direct line of sight, as well as in deep-UV Raman spectroscopy, which enables precise material analysis.