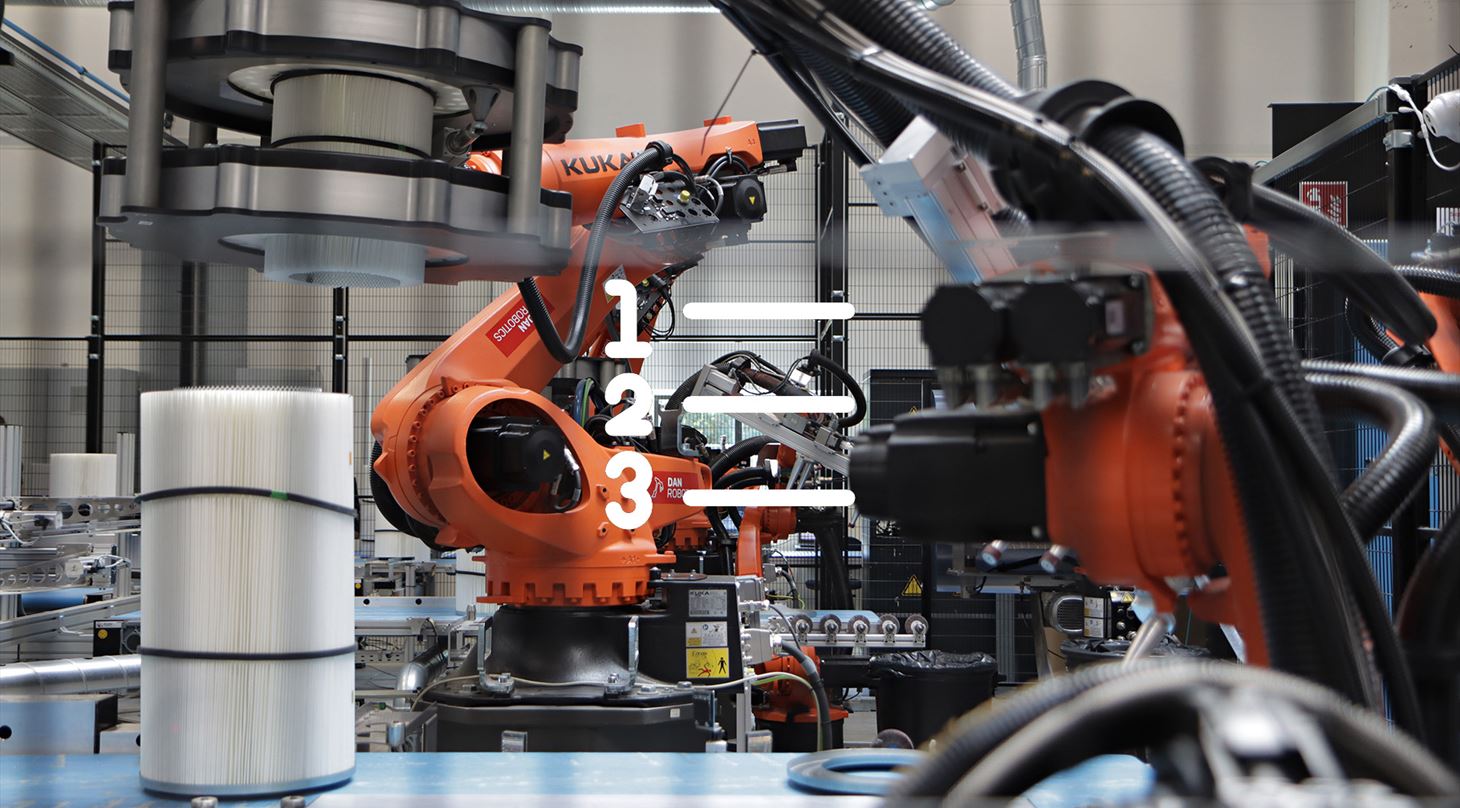

Start your robot journey: Here are six pieces of advice obtained from companies that have learned from experience

Are you on the threshold of a new automation project, or do you have a desire to automate parts of your business in the future? If so, dive into these advice from companies that have had experience with robots.

It is not always easy to take the first step into working with robots, artificial intelligence and the automation of work tasks.

Some companies find it especially difficult, but fortunately there are workarounds for that.

The Danish Technological Institute (DTI) has collected six specific pieces of advice for production companies that wish to automate all or parts of their production.

The good advice has been assembled from the responses of 229 manufacturing companies to a questionnaire-based survey, also in-depth interviews with managers and/or production managers in seven Danish manufacturing companies.

The six good tips

Several of the companies see automation as a necessity in order to remain competitive. And for companies that want to automate, the message is clear:

If your company is to automate your production, it is important that you involve users early on and consider various types of automation including robots and AI, until you are ready to embrace the chosen technologies – and then you must be prepared to push through with the optimisation.

1. Just do it

Jump into automation. Several of the companies interviewed encourage companies to just jump into implementing robots and automation. The technology is available, and you don't have to invent the wheel yourself.

– There is nothing else to do but that. It's just a matter of jumping in and trying it out, says Production Manager Søren Djursland from RIVAL.

2. You don't have to be an expert

The companies emphasize that you do not necessarily have to have specialist skills in robots to be able to automate.

– You don't need to be an expert on robots. The solutions exist -- you just have to find the one that fits your production, says senior project manager Peter Dam Krag from Kohberg.

Although you don't need to be an expert, several people mention that it is a very good idea to ally yourselves with advisers and experts when defining the automation need and scope – so that the best opportunities can be discovered.

3. Involve the end users early

A general piece of advice is to involve the future users early in the implementation process.

– This is one of my hobbyhorses: When we see a machine for the first time, as many as possible of the future users must come along, emphasises Peter Dam Krag from Kohberg.

4. Start small and build on top of that

Companies like RIVAL encourage starting small, and then building on the success, instead of jumping into a big investment from the start.

5. Listen to the experiences of others

The company Slagter Lampe emphasises the value in listening to the experiences of others and drawing on external expertise when choosing the right robot solution.

Maintenance Team Leader Preben Jensen from Pressalit also finds great value in discussing everything from automation to artificial intelligence in an expert group.

6. Be curious about upcoming developments

As managing director Jacob Jensen from S.E.W. North Filtration often says:

– What cannot be done today may be possible tomorrow.

Several of the company managers had the experience that development keeps going forward. Therefore, tasks that were previously inefficient or impossible will eventually become possible with robots – and they are necessary to be able to be competitive. This too can DTI help you with – we can uncover the opportunities that are beyond state of the art.