Robot helps recycle bricks: "We can potentially save a million a year"

A robot can separate cement mortar from bricks and thus strengthen Salling Entreprenørfirma's competitiveness in selling recycled bricks. The company can save one million kroner a year on labour, shows a MADE Demonstration Project in collaboration with DAMRC and the Danish Technological Institute (DTI).

It is slow and expensive to selectively demolish brick walls from 60s and 70s houses to reuse the bricks in new buildings.

– We clean cement mortar from 20-25,000 bricks a year and sell them. It is hard, manual work, and that is why we sought help from MADE to automate this, says Gregers Frederiksen, Director of Salling Entreprenørfirma.

The challenge was first addressed in a MADE Kickstart Project and then in a MADE Demonstration Project, where Salling Entreprenørfirma collaborated with DAMRC and DTI to handle cement mortars, which is much more difficult to remove than lime mortars.

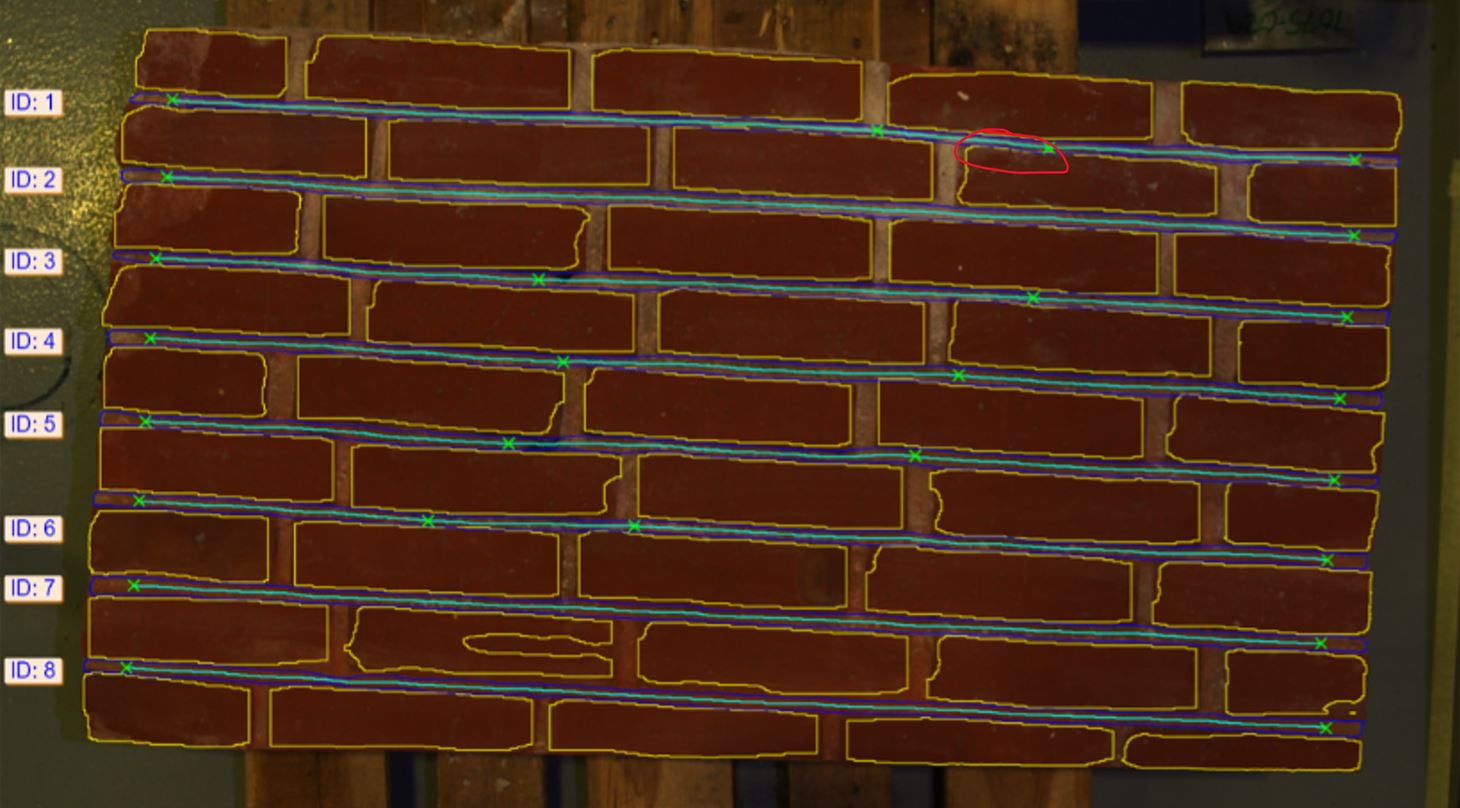

– The project was about getting the robot to move guided by visual input – i.e. an image system – so that it can precisely follow the lines between the brick and mortar, says Anders Bruun Engelbrecht, Project Manager at DAMRC.

– The difficulty has been that the bricks are laid by human hands, so their separation varies by a few millimetres. One challenge is that the dust generated when the wall is torn down can obscure the lines, he adds.

"We are short of manpower here in Skive"

During the two MADE projects, DAMRC has successfully tested 11 brick walls from Salling Entreprenørfirma.

They have been responsible for the robot, while DTI has helped with AI and vision.

– The project showed that it is possible to get a robot to separate bricks and remove cement mortar, and that is good news for us because we are short of labour here in Skive, explains Gregers Frederiksen and continues:

– There is potential for us to save on labour – one million kroner per year, and that means that we can be competitive in sales of recycled bricks.

New construction must contain recycled materials

Today, close to zero percent of bricks in Denmark are recycled, the Danish Ministry of Environment estimates.

Therefore, in March 2024, the Danish Parliament adopted new rules that new construction must include recycled materials (approximately 27 percent of tiles and bricks can be recycled), and Salling Entreprenørfirma wants to be at the forefront of new, green solutions.

– We have no doubt that good business can come from recycling bricks. I believe we can stay within the price range of a special brick of 12-14 kroner, says Gregers Frederiksen.

Salling Entreprenørfirma hopes to have implemented robots within a year. The next step for them is to rent a robot via SMV:Digital.

In the video above you can see a test setup that simulates how the robot will follow the mortar path on a brick wall. In the test setup the robot arm has a marker pen to reduce dust, but in real applications the robot will carry a diamond cutter instead.