Ready for liftoff: 3D printed component in orbit around earth

When two students from the University of Southern Denmark - Thomas Buris Larsen and Sigrid Samsing - had to design a part for launch into space, they chose 3D printing. The Danish Technological Institute was involved in the process to ensure precise and reliable production of the students' design.

The Danish Student CubeSat Program, also known as DISCO, is an educational initiative that allows Danish students to design, build, and launch satellites.

Two of the participants - Thomas Buris Larsen and Sigrid Samsing from the University of Southern Denmark -took on the task of designing a camera holder for the satellite.

Objects sent into space should weigh as little as possible. In this case, we wanted to reduce the weight below a set target, which imposes significant demands on design, material, and manufacturing method. With these requirements in mind, 3D printing was the obvious choice.

- Thomas Buris Larsen, University of Southern Denmark

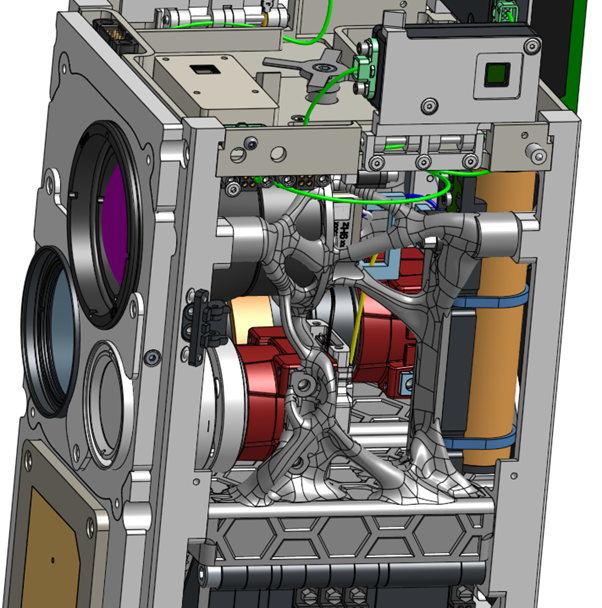

To achieve the desired weight savings, the camera holder was topology optimized and manufactured in aluminum. This method removes all unnecessary material, leaving only what is absolutely necessary.

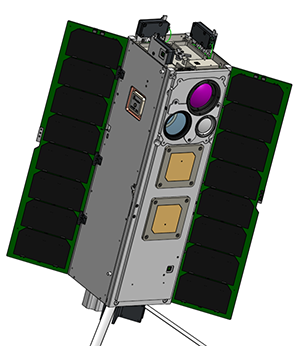

Drawing of the Satellite—The greatest advantage has been the ability to use software to integrate the many components into a single solution that simultaneously accounts for forces in all directions, available space, and weight, says Thomas Buris Larsen.

Drawing of the Satellite—The greatest advantage has been the ability to use software to integrate the many components into a single solution that simultaneously accounts for forces in all directions, available space, and weight, says Thomas Buris Larsen.

To the right is an illustration of the entire satellite. The 3D-printed camera holder will be placed in the upper third behind the three lenses. Image: Thomas Buris Larsen.

Prepared for a rough ride

After the design phase, the component underwent extensive testing to validate its strength and durability.

- Before the bracket was produced, we conducted various simulations to get an idea of how the bracket would react. After production, we performed comprehensive vibration tests to ensure that the part could withstand the forces it would experience during launch, says Thomas Buris Larsen.

With the design and testing successfully completed, the next step is to prepare for the launch of the satellite as part of the Danish Student CubeSat Program. The launch is expected to take place in the summer of 2025.

A look inside the satellite. The camera holder is the gray structure with organic shapes inside the box. Image: Thomas Buris Larsen.

- I am incredibly pleased with our collaboration with the Danish Technological Institute. Additive manufacturing has become a standard technique here on Earth, and now we are working to make it a standard technique in space as well, says Christoffer Karoff, associate professor at the Department of Geoscience at Aarhus University and leader of DISCO.

Once the satellite is in orbit, it will remain in space for up to five years. During this period, it will observe the effects of climate change in and around Greenland. The satellite will, among other things, measure glacier melt, which can provide more precise data on how quickly the ice is disappearing, which is necessary to understand sea-level rise and the broader consequences for the Arctic region.

For the Danish Technological Institute, the case has been particularly interesting as it deals with one of the most demanding industries.

This project is a fantastic opportunity for us to demonstrate how the Danish Technological Institute can help Danes enter the aerospace industry. With a subject clearly designed for 3D printing and optimized with strength-calculated topology, we want to showcase a small selection of the many advantages that 3D printing can offer

- Andreas Aakjær Andersen, Danish Technological Institute