Pinholes and slits for critical applications

At Danish Technological Institute, we can manufacture ultra-precise pinholes and slits in thin films, tailored to meet the most demanding specifications. The pinholes can serve a crucial role as fixed apertures or calibration in optical detection systems, diagnostic instruments and leak testing.

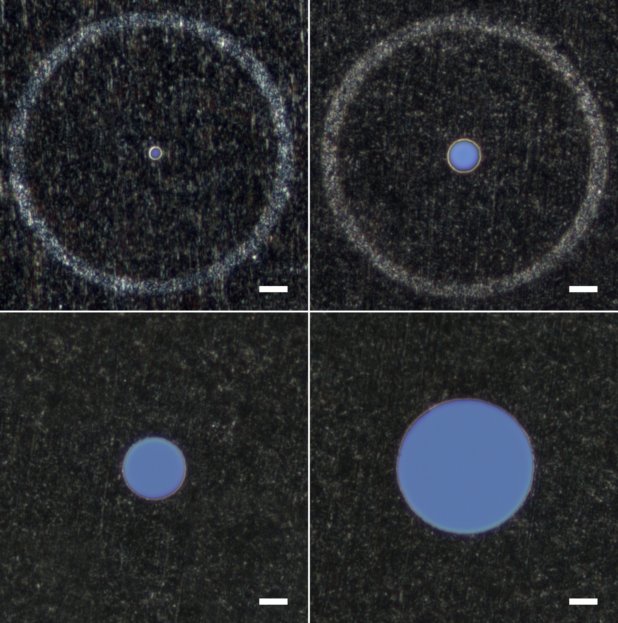

Note regarding images: all scale bars without text label correspond to 10 µm

Specifications, materials and accuracy

In applications where light control, diffraction or detection play a critical role, even the smallest irregularities in pinhole size or shape can compromise performance.

In applications where light control, diffraction or detection play a critical role, even the smallest irregularities in pinhole size or shape can compromise performance.

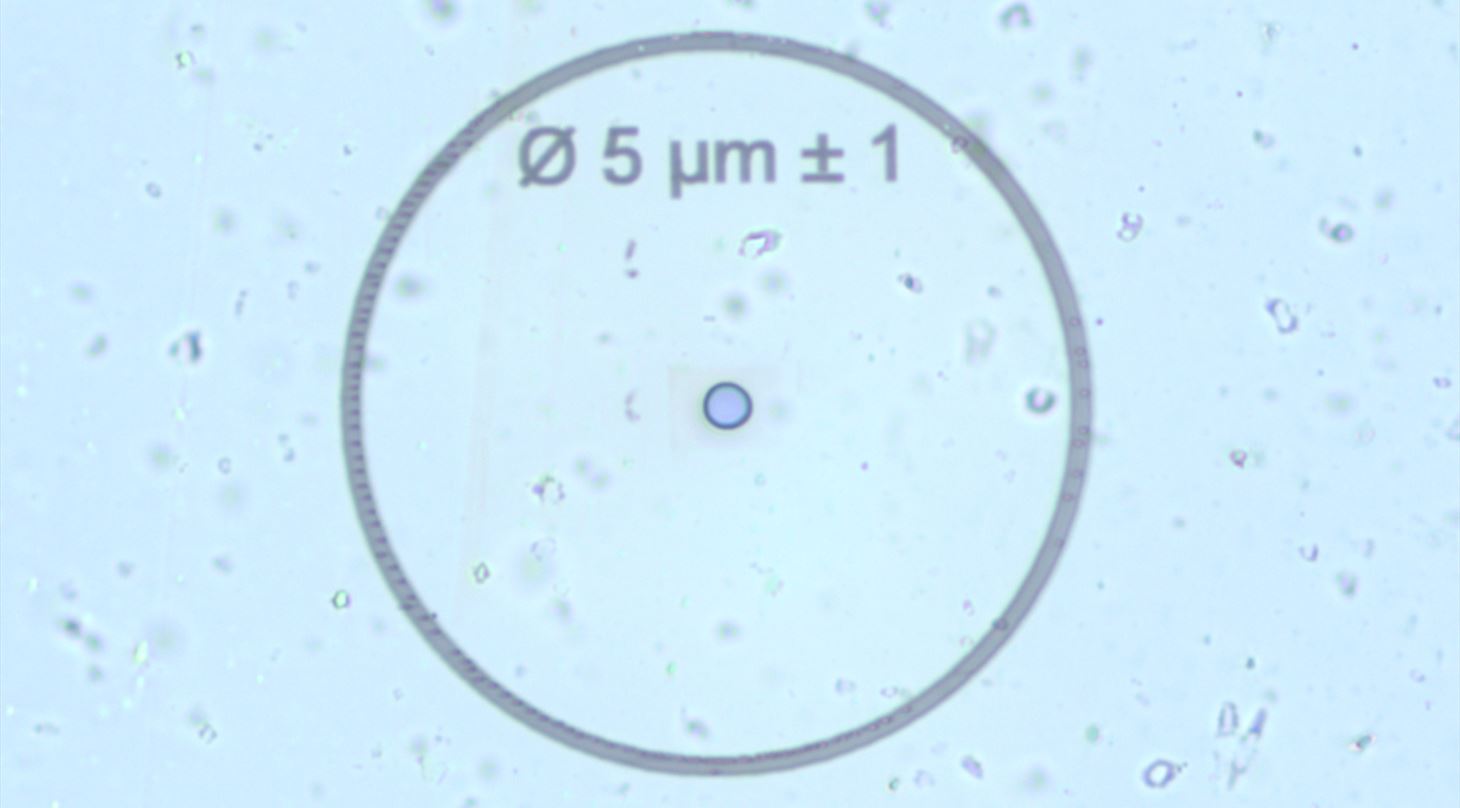

Our manufacturing process ensures each pinhole meets the highest standards - with a dimensional accuracy down to ± 1 µm (0.001 mm).

We can produce pinholes and slits in the range 2-50 microns (0.002-0.050 mm) in diameter. The pinholes can be produced in thin metal films (steel, titanium, ...) and polymer films (PET, polyimide, ...) Films up to ~20 microns (0.02 mm) in thickness can be processed.

We are not limited to circular pinholes, but are also able to produce square holes, slits and other shapes.

Validation and quality control

Validation and quality control

The final dimensions of a produced pinhole can be measured using optical microscopy and electron microscopy.

A calibration certificate can also be provided from an accredited DTI laboratory (subject to pinhole dimensions).

Mounting options and custom solutions

The manufacturing process will be adapted to your needs and limitations set out by the processing equipment.

The film can be mounted in your own fixture or in fixtures manufactured at DTI, for example by 3D printing in polymer or metal. Pinholes can also be processed directly on strips of unmounted film.

Need larger pinholes?

If your application demands larger pinholes or thicker film thicknesses than this production method allows, our laser lab might be able to assist. Pinholes and cutouts can be produced in materials ranging up to 500 microns (0.5 mm) in thickness using laser processing.

Contact Us

Ready to discuss your project? Contact us today to learn how our expertise in precision pinhole manufacturing can ensure exceptional accuracy in your data collection.