New graphene ink enables the smart wearables of the future

'The world's best' graphene ink, which can be used for printed electronics—such as an intelligent t-shirt that measures your pulse—has been developed in collaboration with the Danish Technological Institute in a MADE demonstration project. The newly developed ink has already opened new markets for the company Danish Graphene.

Imagine a super-strong spider web that can bend and stretch without breaking.

This spider web can conduct electricity better than almost anything else. That's how graphene works.

Graphene is a relatively new material. It consists of an ultra-thin lattice of carbon atoms forming a pattern so thin and light that it is almost invisible. It is many times stronger than steel yet still light and flexible, and with its high electrical conductivity, it is an attractive material in a wide range of industries, including electronics, medical technologies, and even water and air purification.

An intelligent t-shirt

Danish Graphene is a Danish company that develops graphene for many purposes. The company wanted to develop graphene in ink form to use it for printed electronics, where surfaces are coated with electrical circuits.

Therefore, they sought help in a MADE material demonstration project, where they received assistance from the Danish Technological Institute.

Graphene ink could be used in smart wearables, such as intelligent t-shirts that can detect small electrical impulses and thus track your pulse, or in training shoes that can analyze your running pattern.

- We wanted to exploit graphene's unique properties to create an electrically conductive ink that can be used in advanced applications like printed electronics. The collaboration with the Danish Technological Institute has allowed us to combine our graphene with a refined ink recipe, so we now have one of the world's best graphene inks. It has opened new opportunities for us, both within existing markets and exciting new applications. Currently, we are also exploring whether the graphene ink can be used in space as a coating against electromagnetic radiation, says Kristian Birk Buhl, CTO at Danish Graphene.

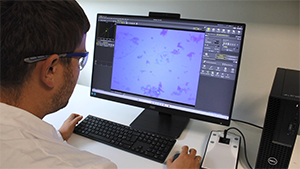

The video below shows the process of manufacturing and testing graphene ink.

Machine Learning led to optimal ink

It took a lot of experiments and adjustments to arrive at the final ink, and to accelerate the investigations, a 'fail fast' approach was used, which included Machine Learning, where computing power is used to analyze data and predict outcomes.

- By using Machine Learning, we could quickly see which ingredients and conditions had the greatest effect on the ink's electrical conductivity. This allowed us to significantly shorten the development time because we could focus our experiments on the most promising combinations and quickly discard the less promising ones—hence the term 'fail fast', explains Zachary J. Davis, vice director at the Danish Technological Institute.

MADE project accelerated innovation

MADE project accelerated innovation

Kristian Birk Buhl is very satisfied with the project's output:

- We have achieved some really promising results, confirming our graphene ink's potential to compete with the best on the market. Normally, we would have spent much more time and resources to achieve these results, but the collaboration has made it possible to accelerate the process significantly, he says.

The strength of the project has been that we have been able to combine our graphene expertise with the Danish Technological Institute's experience in ink formulation and testing, which has made it possible to achieve results quickly. Normally, it would require much more time, money, and research

- Kristian Birk Buhl, Danish Graphene

With a so-called proof of concept in hand, Danish Graphene is now ready to proceed with development to approach a market-ready product.

- We also need to look at how the ink can be integrated into commercial applications. We know that the ink is particularly well-suited for smart wearables, as these applications require high electrical conductivity, and not least because graphene, unlike other materials, is not harmful to the skin, Kristian Birk Buhl concludes.

About MADE demonstration projects

With a MADE Demonstrations Project, a small or medium-sized company can receive up to 100,000 DKK in support to solve a specific challenge in the company or test a new technology in production. By being connected with the Danish Technological Institute, FORCE Technology, Alexandra Institute, or DAMRC, one gains access to the technologies, knowledge, and expertise necessary to address the specific challenge in the company. This can be within materials or production. MADE demonstration projects are co-financed by the European Regional Development Fund and the Danish Executive Board for Business Development and Growth. Would you like to hear more about the opportunities to test and demonstrate new solutions in MADE? Please reach out to MADE - they cover all of Production Denmark.

This article is originally published by MADE