Impact resistance testing

Machinery failures can lead to dangerous situations, so ensuring worker safety and compliance with safety standards is paramount.

Our impact resistance test assures that materials used in protective applications can withstand extreme conditions, safeguarding personnel and minimizing risk.

Testing impact resistance

The service is conducted in accordance with the DS/EN ISO 14120:2015 Annex B standard, a rigorous international guideline for impact testing. The test simulates scenarios where a machine failure could result in high-velocity projectiles, such as metal fragments, being expelled. By using projectiles shot at high speeds, the tests replicate real-world conditions where materials must provide effective barriers against such hazards.

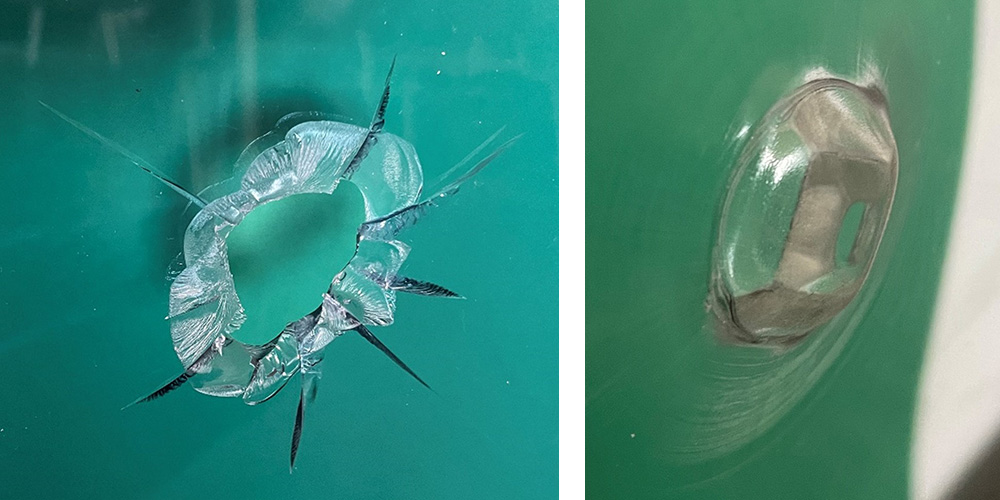

Figure 1: Selecting the correct material for safety guards are crucial for safety in the workplace.

Safety benefits

Testing materials against high-speed impacts ensures that protective barriers and equipment can withstand hazards, reducing injury risks in industrial settings. The service provides insights into polymer performance, aiding in the selection of materials that offer optimal impact protection and energy dissipation. Passing these tests also minimizes equipment damage, lowering downtime and maintenance costs, and enhancing workplace safety and efficiency.

We can assist you with the following activities:

- Conducting impact resistance tests on polymer materials to evaluate their performance under high-speed impact conditions.

- Providing detailed reports and analysis to help in selecting materials that offer optimal protection and durability.

- Ensuring compliance with international safety standards, such as DS/EN ISO 14120:2015, to meet industry regulations.