Fully electric: MADE project opens the door to new markets

New knowledge about technology for current leads has provided the company Mark & Wedell with entirely new business opportunities. This is the result of a MADE project in collaboration with the Danish Technological Institute.

How do we gain knowledge about a new technology?

This question preoccupied Mark & Wedell when their current supplier of HTS tapes withdrew from the market. This meant they needed to find a new supplier – and at the same time switch to the next generation of HTS tapes.

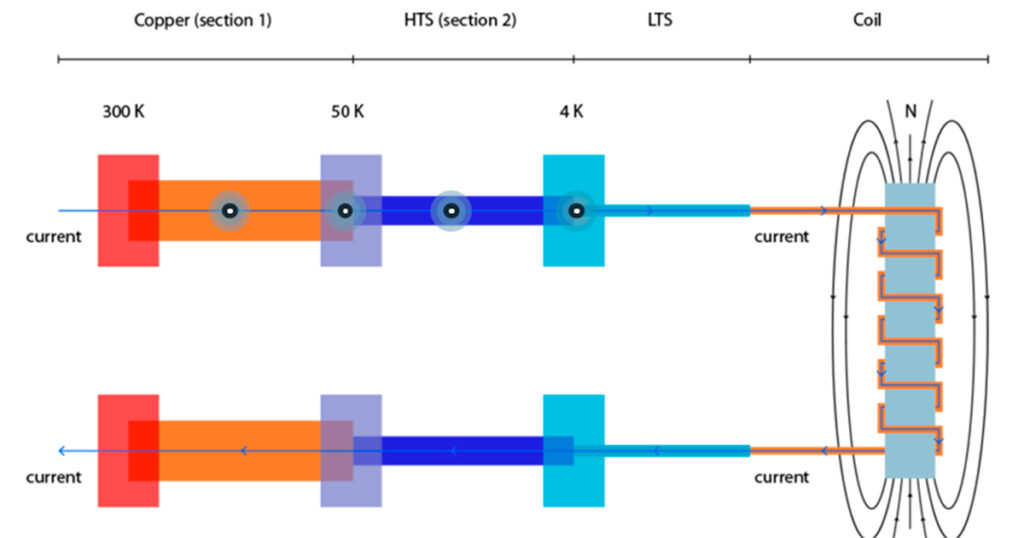

Mark & Wedell develops and produces superconducting current leads – advanced electrical connections that can conduct large currents from room temperature down to extremely low temperatures of -271.15 °C (also known as 2 kelvin). This technology is indispensable in demanding facilities, such as the particle accelerator at CERN, superconducting magnets in fusion reactors, and coils in modern MRI scanners.

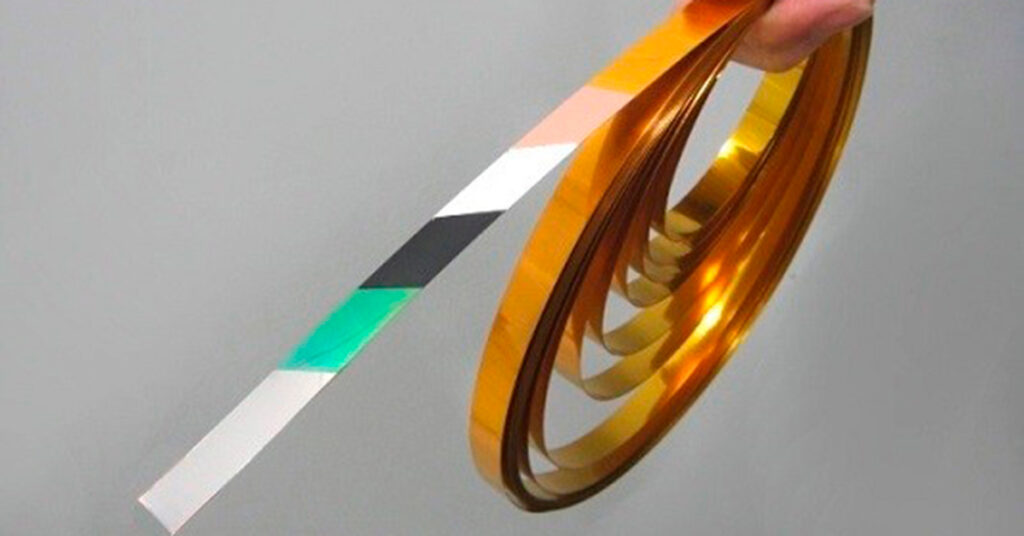

An essential component of Mark & Wedell’s current leads is high-temperature superconducting tapes (HTS tapes), which ensure that current can be transported efficiently and reliably in and out of superconducting coils with minimal losses. For many years, Mark & Wedell had relied on the same supplier of HTS tapes but had to rethink their approach when this supplier decided to cease production.

Photo: Fujikura Ltd. HTS tape consists of multiple layers. At the core is the superconducting layer, which can carry current without loss. Surrounding it are buffer and protective layers that safeguard and stabilize the tape.

- It was a serious problem. We had been considering switching to the next generation of HTS tapes for some time, but now we were forced to do so and had to react to the situation, says Torben Ekvall, CEO and co-owner of Mark & Wedell.

The next generation of HTS tapes represents a technological upgrade, capable of transporting even higher current densities and being more flexible in their applications. Compared to previous generations, they are less fragile and can be better adapted to the ideal design of a current lead.

However, switching to the new generation is also technologically complex and first requires a good understanding of the market, followed by an in-depth knowledge of the materials. Therefore, Mark & Wedell sought assistance through a MADE demonstration project, where they received support from the Danish Technological Institute.

MADE accelerated the solution

- We needed help to navigate safely through the challenges associated with transitioning to the new technology. It was critical for us to find the right partners and ensure that we could make the transition with as low a risk as possible, explains Torben Ekvall.

The Danish Technological Institute began by screening the market, identifying potential suppliers, and analyzing their technologies.

Illustration: Mark & Wedell. HTS tapes (dark blue) are shown here in context. The current is cooled down before it reaches the HTS section, where it is transported without energy loss. It is then wound around the coil (gray), generating a powerful magnetic field that is used to drive advanced technologies. After the coil, the current flows back through the system in a closed circuit to maintain the magnetic field.

- We examined, among other things, the materials' current capacity and durability, as well as how much HTS tape each supplier could deliver. We also performed calculations on the materials' heat transport and conducted detailed investigations into the construction of the HTS tapes to ensure both safety and high performance, says Nikolaj Zangenberg, center manager at the Danish Technological Institute.

The project resulted in a shortlist of five potential suppliers of HTS tapes, three of which provided product samples for further testing. One supplier, Faraday Factory, quickly stood out.

- Faraday Factory from Japan showed from day one that they understood our need for a stable supplier of HTS tapes that could meet our quality and reliability requirements. They were very professional and proactive, showing great interest in working with us. This made them the obvious choice, says Torben Ekvall.

New technology secures the future and opens new markets

The MADE project provided us with knowledge and resources that we otherwise would not have had access to. The result is that we are now in a position to continue delivering advanced solutions to our customers. At the same time, the new generation of HTS tapes allows us to create more flexible solutions, making us more attractive to wind farms, fusion energy projects, and other industrial applications

- Torben Ekvall, Mark & Wedell

What are HTS Tapes?

- HTS stands for “High Temperature Superconducting.”

- HTS tapes are thin, flexible strips that enable the conduction of large amounts of current without energy loss.

- HTS tapes are used as superconducting components in systems such as current leads and cables.

- Common applications include energy systems, particle accelerators, and magnetic systems.

About MADE demonstration projects

With a MADE Demonstrations Project, a small or medium-sized company can receive up to 100,000 DKK in support to solve a specific challenge in the company or test a new technology in production.

By being connected with the Danish Technological Institute, FORCE Technology, Alexandra Institute, or DAMRC, one gains access to the technologies, knowledge, and expertise necessary to address the specific challenge in the company. This can be within materials or production.

MADE demonstration projects are co-financed by the European Regional Development Fund and the Danish Executive Board for Business Development and Growth. Would you like to hear more about the opportunities to test and demonstrate new solutions in MADE? Please reach out to MADE - they cover all of Production Denmark.

The article is originally published by MADE