Industrial robots of the future must think for themselves to a much greater extent (and reduce a special type of waste)

20 August 2024

A new project will use artificial intelligence to give robots the opportunity to adapt to unforeseen events and new scenarios in the automated tasks of the future.

Fewer restrictions, extended adaptability and great reliability.

Artificial intelligence (AI) brings with it many new possibilities – also when it comes to the control of robots, which in the future must be able to adapt and manage themselves to a much greater extent than is the case today.

A new EU project called RoboSapiens (Robotic Safe Adaptation In Unprecedented Situations) will, among other things, help towards this.

The Danish Technological Institute (DTI) is a partner in the RoboSapiens project, which is led by Aarhus University. Together with many other partners, DTI will try to give tomorrow's robots the ability to adapt to major and unforeseen changes in their environment – and to work closely with humans.

– The aim of the project is to use AI to help robots to adapt themselves to the conditions around them – including conditions with large, unforeseen changes – with fewer restrictions. In this connection we are working on developing some safety techniques that ensure the robot's trustworthiness, operation and safety in the work, says Mikkel Labori Olsen, who is Product Manager at DTI.

The project's four central impact points

In order to achieve the goals of the project, which runs from 1 January 2024 to 31 December 2027, the partners are working on four main goals.

1. The project will ensure a robotic technology with many new possibilities for self-adaptation in response to unusual and unforeseen changes in the system structure and / or environment.

2. The project will promote safety software that connects tightly to the robot technologies, so that robot safety is top notch both before, during and after the robots' self-adaptation.

3.The project will use deep learning techniques to actively reduce uncertainty in connection with robotic self-adaptation.

4. The project will generally ensure that the individual systems are trustworthy, so that robots can adapt to the outside world on their own with the help of deep learning and IT architecture without compromising the credibility of the work.

DTI focuses on refurbishment

The project's results are demonstrated in four different user cases in order to show that they meet the RoboSapiens project's overall goals.

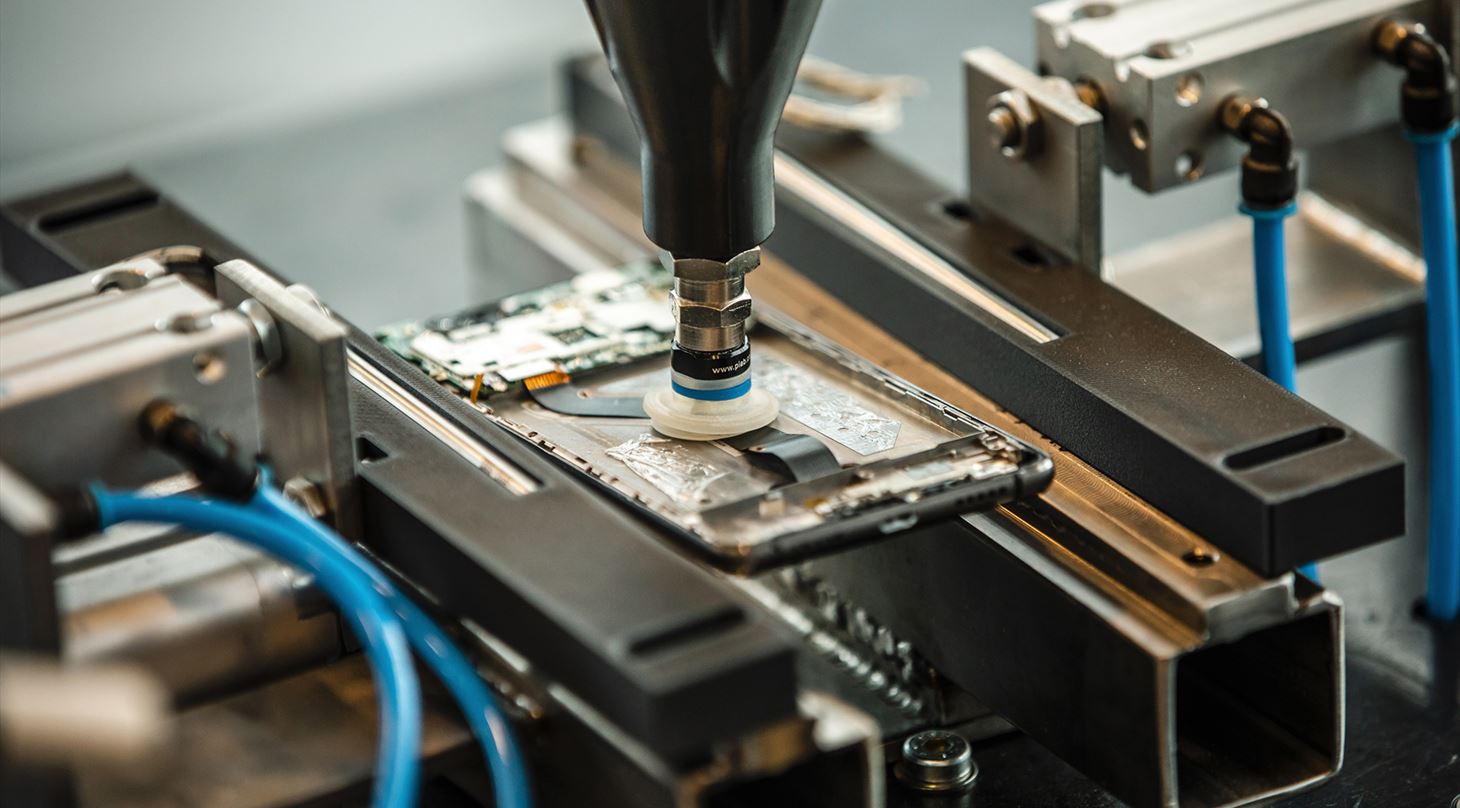

For DTI, the focus is on refurbishment – the renovation of products that would otherwise be scrapped.

DTI will also take a closer look at topics as diverse as: Navigation of autonomous ships, navigation of warehouse robot swarms and interactions between humans and robots.

– Robots have over time helped a lot in increasing production. In our user case, we will now take a closer look at how robot automation can scale up circular processes, so that we can extend the life of products instead of producing new ones. Here we look more specifically at refurbishment of laptops and what can be automated in this area, says Mikkel Labori Olsen.

53.6 million tons, which is 9,000 times the weight of Copenhagen’s Round Tower. This is how much electronic waste the world produces every year, according to a UN report. This figure continues to rise as a result of: increased consumption of electrical equipment, short life cycles, and few opportunities for repair. A trend which, among others, the company Tier1 Asset is trying to counteract. Read more

Crucial for future production

The four user cases in the RoboSapiens project cover a wide spectrum of applications, but they all share the common challenge that they involve tasks with great variety that traditional robots often find it difficult to adapt to.

According to Mikkel Labori Olsen, this underlines a significant limitation in today's automation technology, where flexibility often has to give way to efficiency.

– RoboSapiens will demonstrate how artificial intelligence and dynamic routines can be used to train and control a robot, making it possible for robots to continuously adapt to a wide range of environments and usage scenarios while maintaining a high degree of efficiency and safety. Artificial intelligence, used correctly in good processes, has the potential to revolutionise industrial automation by combining unprecedented flexibility with the traditional strengths of robotics. Therefore, the results from RoboSapiens can also have a great impact on the way companies manufacture in the future, he says.

A large number of partners are involved in the project, which is run by Aarhus University. In addition to DTI, the partner list includes: University of Antwerp, Aristotle University of Thessaloniki, Norwegian University of Science and Technology, University of York, PAL Robotics, Fraunhofer IFF, ISDI Accelerator and Simula Research Lab. The project is financed by Horizon Europe's research and innovation program (2021-2027).