Glass-ceramic coatings - Introduction to chemical surface treatments

Select Page

The Danish Technological Institute develops surface coatings with special properties that can optimize both production and products and thus pave the way for increased revenue.

Even small changes to a surface can have a great effect in terms of savings, increased service life and elimination of surface problems - both on products and production facilities.

At the Danish Technological Institute, we have nearly 20 years of experience in developing, testing, and implementing functional surface coatings – i.e. coatings that have unique properties such as dirt-repellence / ease of cleaning, ice-repellence, corrosion protection or scratch resistance.

With our expert knowledge in the field, we offer advice on surface coatings, just as we test products for solving surface technology problems.

ANTIFOULING COATINGS FOR THE OIL INDUSTRY

Get an overview of our coating properties and their benefits

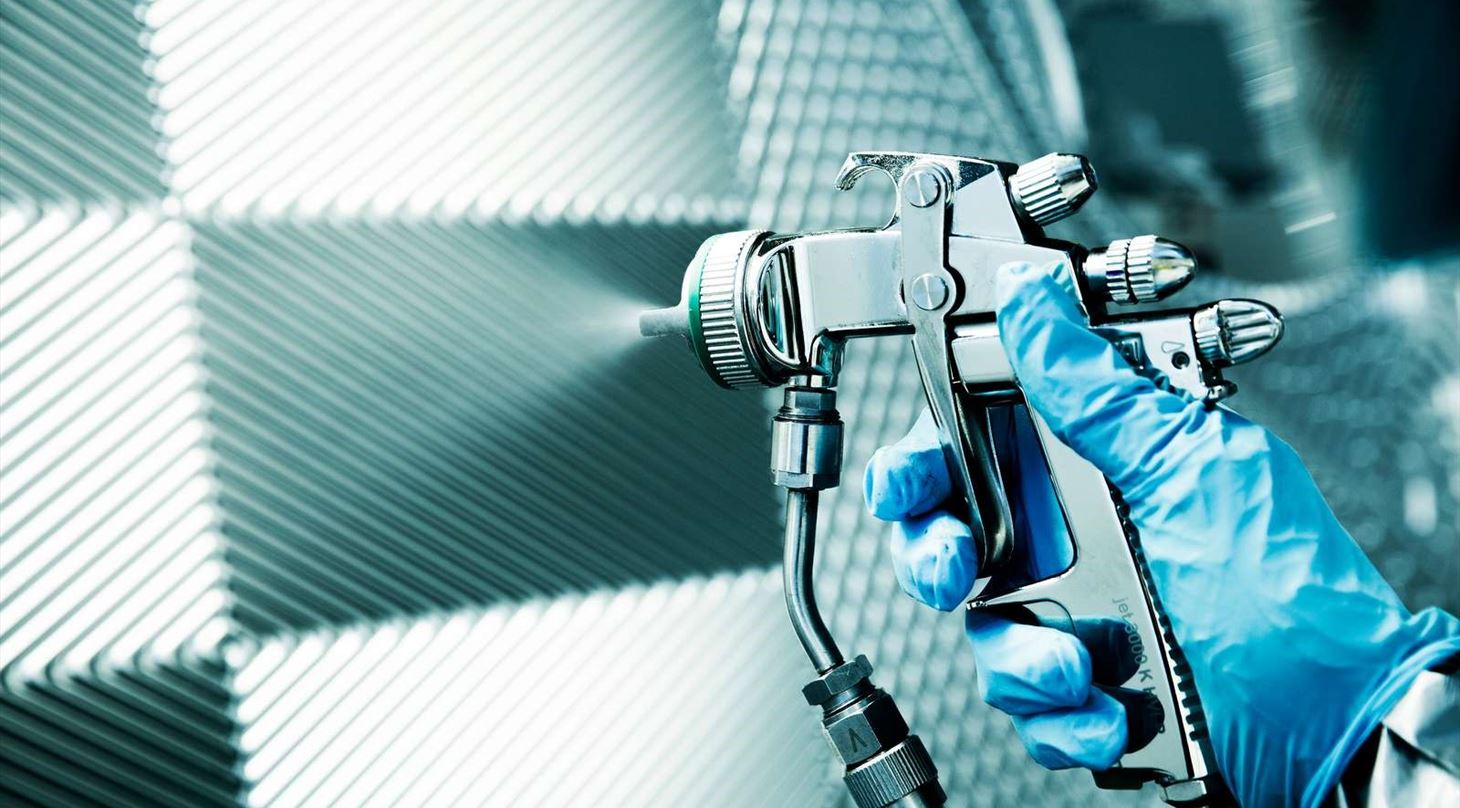

In our laboratory facilities, we develop new, functional surface coatings, e.g. by using sol-gel technology, and we combine these functional surface coatings with existing coating types such as epoxy and polyurethane. The liquid functional coatings can be applied to a wide variety of metals, including aluminum, stainless steel, duplex, inconel, titanium, copper and gold. Furthermore, we have experience with items in glass and polymer. Simple application methods such as spray and deep coating make it possible to apply coating on items with complicated geometry. The applied coatings are typically cured at 80-200 ⁰C until the finished functional surface coating is obtained.

In our laboratory facilities, we develop new, functional surface coatings, e.g. by using sol-gel technology, and we combine these functional surface coatings with existing coating types such as epoxy and polyurethane. The liquid functional coatings can be applied to a wide variety of metals, including aluminum, stainless steel, duplex, inconel, titanium, copper and gold. Furthermore, we have experience with items in glass and polymer. Simple application methods such as spray and deep coating make it possible to apply coating on items with complicated geometry. The applied coatings are typically cured at 80-200 ⁰C until the finished functional surface coating is obtained.

The Danish Technological Institute has developed several different functional surface coatings that can be tested to solve your surface challenges. In a dialogue with you, we select the most suitable coatings for application testing in our own facilities. To characterize the surface coating, we have various test equipment available – e.g. for testing layer thickness, adhesion, and surface energy - as well as more advanced equipment such as Scanning Electron Microscope (SEM), condensation chamber and ice tester.

The Danish Technological Institute has developed several different functional surface coatings that can be tested to solve your surface challenges. In a dialogue with you, we select the most suitable coatings for application testing in our own facilities. To characterize the surface coating, we have various test equipment available – e.g. for testing layer thickness, adhesion, and surface energy - as well as more advanced equipment such as Scanning Electron Microscope (SEM), condensation chamber and ice tester.

Through characterization and testing of various functional surface coatings, we will collaborate with you to select the most promising candidate or candidates for on-site tests. Based on these experiments, the market maturity of the tested coatings is assessed. We have our own pilot-scale application facilities with a curing oven (1.5 x 2 x 3 m oven compartment), which allows us to handle series of items.

How can the Danish Technological Institute help you?

How can the Danish Technological Institute help you?

- Advice on surface technology issues

- Screening of surface coatings

- Testing of products to solve a surface technology problem

- Development and adaptation of sol-gel varnishes for a specifically defined purpose

- Project collaboration in the development of new surface properties