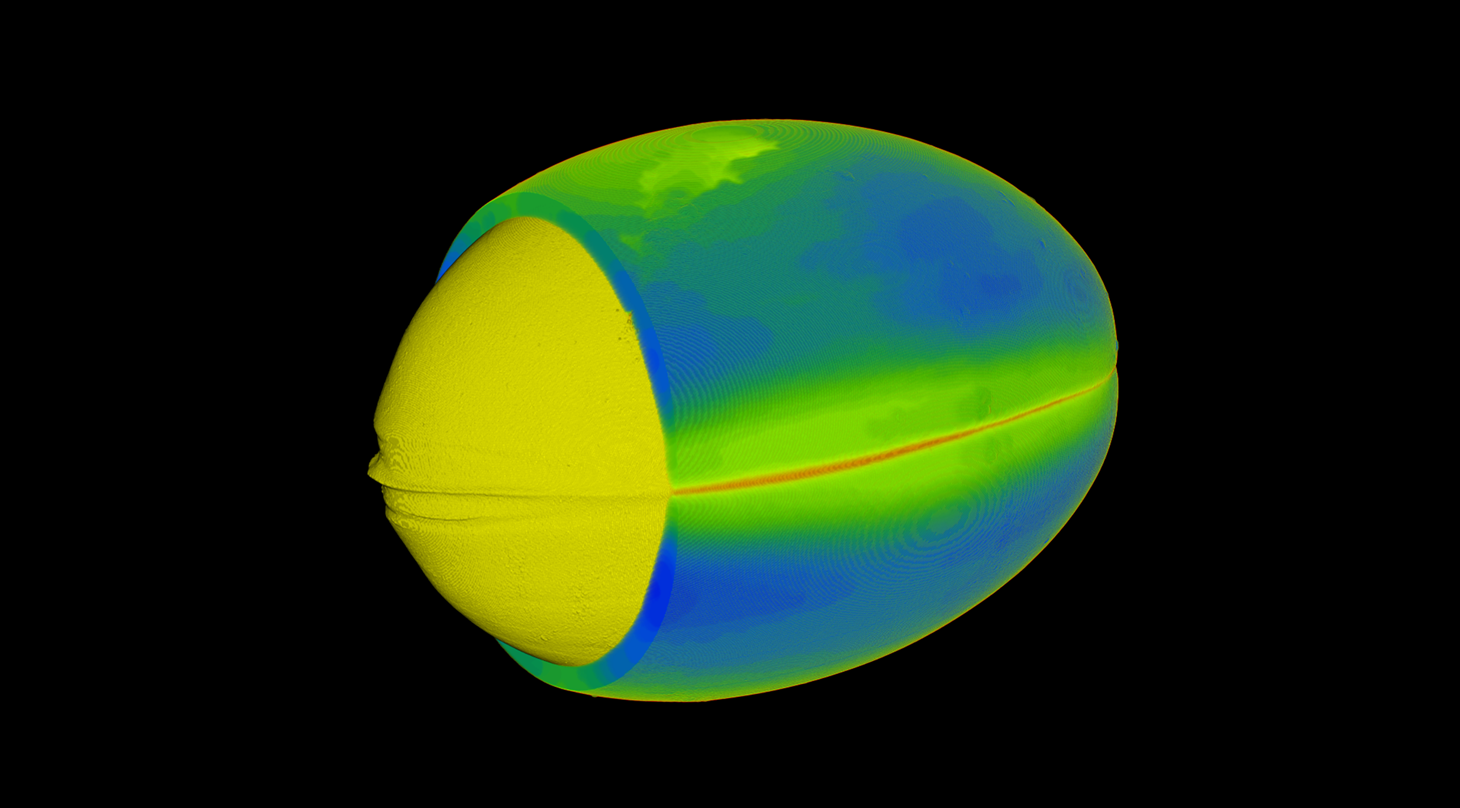

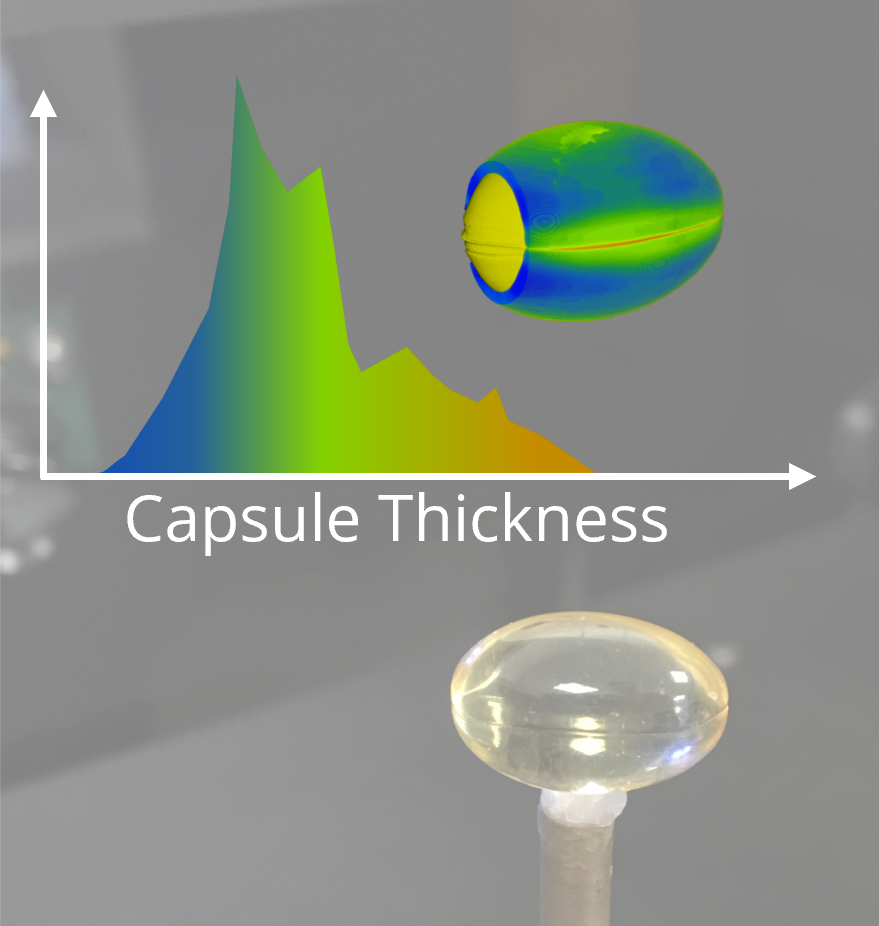

Capsule thickness in 3D

Investigate coatings and multi-component materials with Micro-CT

Do you need to know how a coating is covering a surface? Do you need to analyze the volume distribution in a complex material? These insights can be vital for your product development.

Micro-CT scanning enables non-destructive 3D analysis of small samples and products, making it a useful tool for understanding where your materials are in your product. We can measure objects ranging in size from 0.5 mm up to a few centimeters in diameter, with visualization and analysis possible for features from 1 to 25 µm.

In this study, the weaknesses and flaws in a fish oil supplement pill was identified by measuring and visualizing the capsule thickness. Such informations are critical for the product quality. In addition, Micro-CT allows determination of the capsule and fish oil volumes, providing detailed insights into the pill's design and composition. The results can be applied to improve manufacturing processes, ensure compliance with quality standards, and optimize product performance.

Our results

Our results

Our Micro-CT investigation of a fish oil supplement pill shows that:

- The thinnest part of the capsule is identified in the welded joint on the side of the pill.

- The corresponding thickness on the other side of the capsule is relatively thick, which indicates the production process can be optimized to improve the durability of the capsule.

- The volume weighted average capsule thickness is calculated to 446 µm.

- The thinnest and thickest parts are measured to 252 µm and 705 µm thickness respectively.

- The fish oil enclosed by the capsule has a volume of 0.54 cm3

Our Process

The step-by-step video shown below is an example of how an investigation can be undertaken.

While we here demonstrate the use of Micro-CT for a capsule study, the method is well suited for a variety of different material types and purposes, for example materials development, inspection of hidden elements or non-destructive fault analysis. Typical applications are within medical devices, porous materials, composite materials, 3D printed materials, and electronic and micromechanic components and products.

Additional Techniques

Beyond Micro-CT, we offer a suite of complementary techniques for material investigation. Whether you need additional imaging methods or material testing, we have the tools and expertise to meet your needs.

Contact Us

Ready to enhance the quality and integrity of your materials? Please contact our specialist Susan Rudd Cooper for more information. She can be reached at srco@dti.dk or +45 7220 1754.