Characterization of composites

At the Danish Technological Institute, we specialize in the characterization of composite materials on both small and large length scales.

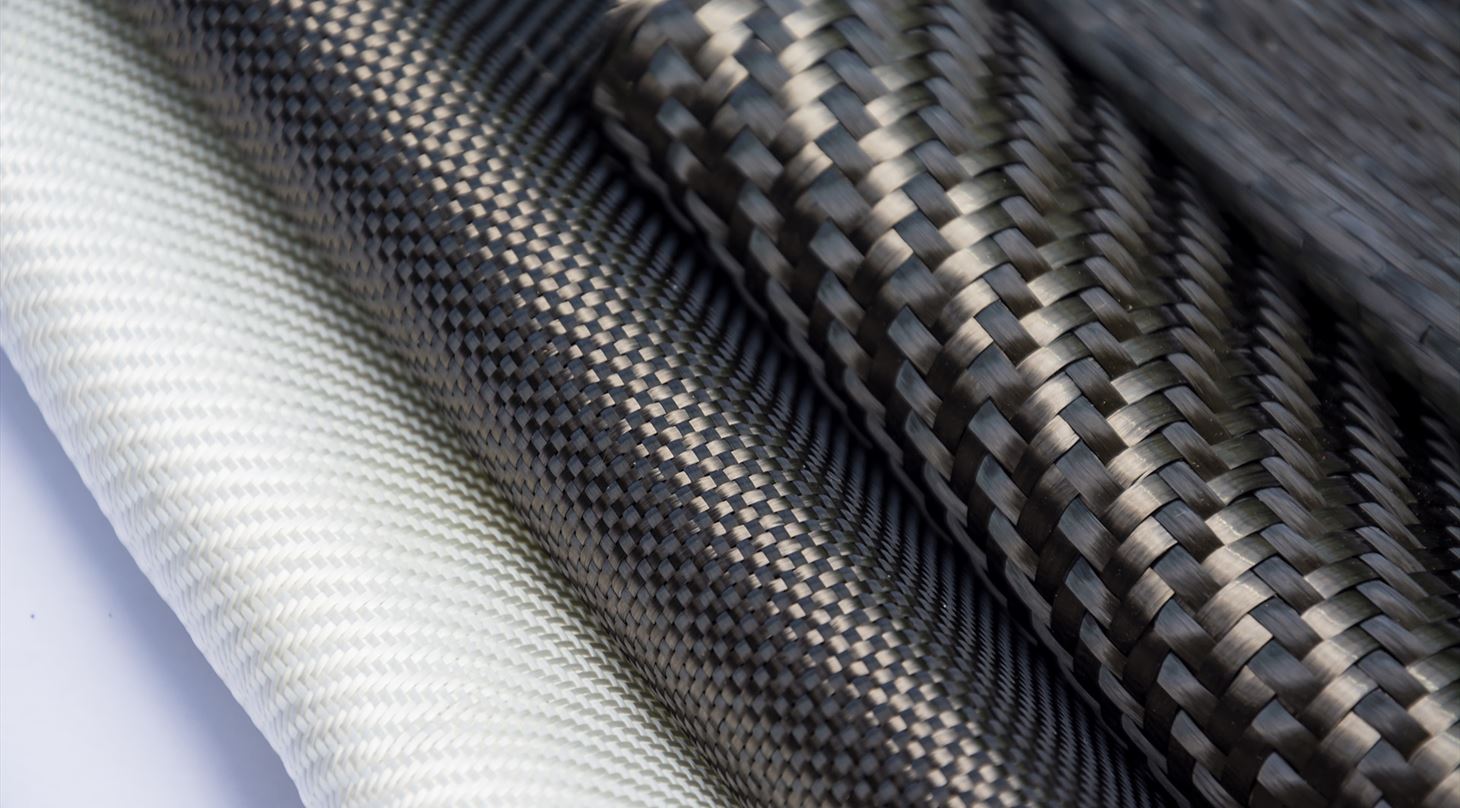

Composite materials consist of two or more components, each of which can have vastly different properties compared to the composite material. Typically speaking, the composite consists of a binder (also called the matrix) and reinforcing elements such as fibers, particles, or plates.

Properties and Challenges

The properties of composite materials are determined by both the individual properties of the components (e.g., matrix and fiber), as well as the interactions between the components. Therefore, an understanding of the properties of composite materials requires not only an accurate understanding of the individual components but also an understanding of the interaction between them. Incorrect material compositions or incorrect processing and treatment can lead to sub-optimal and undesirable properties, such as:

- Cracks in the matrix and at interfaces

- Delamination

- Porosity in the matrix or between individual fibers

- Inhomogeneity

Characterization of Composites

The Danish Technological Institute offer advanced characterization techniques, including:

- 3D Visualization and quantification of porosities: porosities can develop during processing, and by using X-ray and neutron radiation, we can visualize porosities with spatial resolution on a micrometer scale or even smaller.

- Understanding the interface between components: interfaces are critical for the properties of the composite materials, and it is often where defects form.

- Quantification of fiber length, density, and orientation: the properties of fiber-reinforced composites are closely related to the distribution of the reinforcing fibers in the matrix.

- Quantification of particle size and distribution: composites with nanoparticles often require high-quality dispersion and control of particle size.

- Failure analysis and quality assurance: our analysis methods can help troubleshoot and quality-assure composite materials – we also provide input for improvements.

We can also analyze composites in situ, i.e., during a process, to understand changes in properties under the influence of mechanical stress, temperature, or pressure.

Types of Composite Materials we specialize in

Different composite materials have unique properties and applications. We can, among other things, help analyze:

- Fiber-reinforced polymer (FRP): Materials where fibers such as glass, carbon, or aramid (e.g., Kevlar®) are embedded in a polymer matrix, e.g., glass fiber-reinforced epoxy.

- Metal Matrix Composites (MMC): Materials consisting of a metal matrix, e.g., aluminum, with embedded ceramic particles or fibers to improve strength and wear resistance.

- Ceramic Matrix Composites (CMC): Composite materials where ceramic fibers are embedded in a ceramic matrix, resulting in materials with high temperature resistance and strength.

- Nanocomposites: Materials consisting of a polymer matrix with embedded nanoparticles, which can improve mechanical, thermal, or electrical properties.

Ready to enhance the performance and reliability of your composites? Contact us today to discover how our cutting-edge characterization solutions can benefit your product!